An Innovative Approach to Identifying Air Door Timings Using Wind Speed Data

In the realm of environmental control within large facilities, the monitoring and management of air flow are critical. A recent study published in Scientific Reports introduces a sophisticated method for identifying air door opening and closing times, alongside a stage division process, by leveraging wind speed data collected from a single sensor. This methodological breakthrough promises to enhance operational efficiency and safety in environments where air door regulation is pivotal. Let’s delve into the methodology and implications of this groundbreaking research.

The Architectural Framework

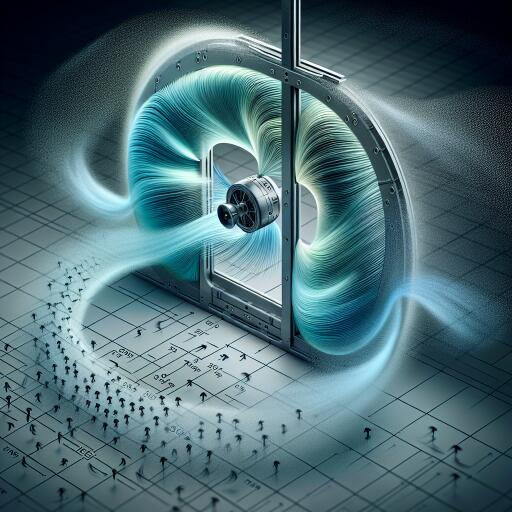

The proposed method unfolds in four intricate steps, designed to process wind speed sensor data and deduce air door dynamics accurately. Initially, the data undergo preprocessing to normalize and discretize the time series, making it suitable for further analysis. Following this, a classification process extracts feature vectors from the preprocessed data to categorize the air door’s operational states. The third step involves merging and selecting the optimal time series data that represent the air door’s movements accurately. Lastly, the model corrects and refines the door’s opening and closing times through regression models, offering a precise depiction of the air door’s behavior.

Preprocessing Precision

The preprocessing step is pivotal, involving the normalization of wind speed data to a uniform scale and its division into manageable, discrete segments through a multiscale sliding window approach. This meticulous process ensures the data is primed for accurate classification, highlighting the method’s rigorous foundation.

Classification and Feature Extraction

Employing both traditional statistics and discrete wavelet transform techniques, the study extracts a comprehensive set of feature vectors from the segmented data. These vectors, embodying the essence of the air door’s operational nuances, undergo a dual-model classification process that discerns the door’s specific states—whether in motion or stationary.

Merging, Selection, and Correction

Upon classification, the method emphasizes merging overlapping data segments and selecting the most representative time series through an innovative Intersection over Union (IoU) metric. This step ensures the elimination of redundant or irrelevant data, honing in on the most accurate representation of the air door’s activity. The final correction phase involves four regression models that fine-tune the door’s operational timelines, offering unprecedented precision in identifying and categorizing its opening, fixed-angle, and closing stages.

Technological Implications

This air door time identification and stage division method, underpinned by wind speed data from a singular sensor, sets a new standard for environmental control within facilities. It presents a practical solution for optimizing air flow, energy consumption, and safety protocols. Through this research, facilities can now harness the power of data analytics to streamline their operations and foster a safer, more efficient environment.

Conclusion

The study elucidated in Scientific Reports not only showcases a novel application of sensor data in operational optimization but also underscores the importance of precision, data analytics, and methodological rigor in the pursuit of technological advancement. As we move forward, the integration of such methodologies into the fabric of environmental control systems marks a significant leap toward smarter, more responsive infrastructure capable of adapting to the nuanced demands of modern facilities.

By pushing the boundaries of what’s possible with data analysis, this method provides a glimpse into the future of facility management—where precision, efficiency, and safety converge seamlessly.