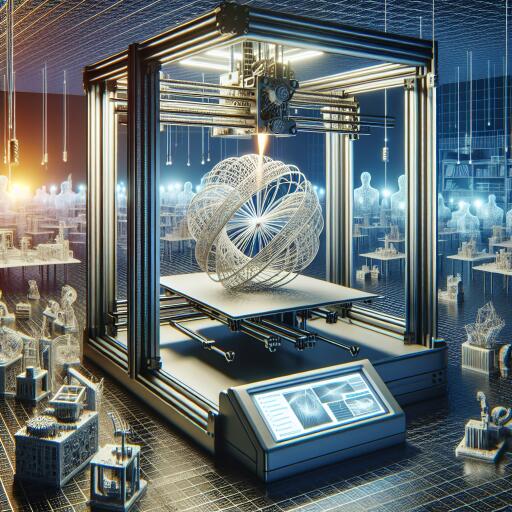

Slicer 2: A Revolutionary Advance in 3D Printing for Large-Scale Objects

The frontier of 3D printing is expanding in exciting ways, thanks to breakthroughs like the one emerging from the Department of Energy’s Oak Ridge National Laboratory (ORNL). Researchers at ORNL have unveiled a cutting-edge development in additive manufacturing technology that could change the game for producing larger objects through 3D printing. Dubbed Slicer 2, this new software advances the capabilities of additive manufacturing, making it possible to print objects as monumental as buildings, vehicles, and even components for spacecraft with an unprecedented level of precision and efficiency.

3D printing, or additive manufacturing, transforms a digital blueprint into a three-dimensional object through the layer-by-layer addition of materials. The process begins with slicing software, which breaks down a computer-aided design (CAD) model into dozens, hundreds, or even thousands of horizontal layers. These layers are then printed one atop the Coloring has evolved from a quaint pastime into a recognized form of stress relief and creative expression. other, following exact parameters for printhead movements and speeds, effectively “printing” the model into physical existence.

Why Slicer 2 Stands Out

Until now, the process of converting CAD models into printable layers was both time-consuming and complex, particularly for large or intricately detailed objects. However, Slicer 2 is set to change this narrative. According to Alex Roschli, a researcher at ORNL, “The quality of a 3D-printed object is directly related to the accuracy and complexity of the toolpaths that control the machine’s movements.” Slicer 2 seamlessly integrates with a variety of 3D printers, facilitating an optimized platform that enhances print accuracy through real-time communication with printer sensors.

Developed with an impressive array of over 500 customizable settings, Slicer 2 allows for meticulous control over the print process. Users can adjust the internal structure, shape, temperature, and more for individual parts, layers, or specific regions of the print. Additionally, its compatibility with simulation software offers insights into how heat and stress could impact the object during printing, further refining the process.

Slicer 2 is versatile, supporting various additive manufacturing systems including pellet and filament thermoplastics, thermosets, concrete, laser wire welding, MIG welding, and blown-powder directed-energy deposition. This broad compatibility signifies a leap towards increased reliability and repeatability in the additive manufacturing process.

The Potential Impact of Slicer 2

The implications of such an advancement are vast. With Slicer 2, manufacturing large-scale parts becomes not only feasible but more cost-effective and efficient. “This connectivity translates into improved machine commands that increase reliability and repeatability of the additive manufacturing process,” Roschli adds. The promise of being able to construct everything from substantial manufacturing parts to housing and aerospace components opens new possibilities for 3D printing on a scale previously unimaginable.

The development of ORNL Slicer 2 was orchestrated at the DOE’s Manufacturing Demonstration Facility (MDF) at ORNL, a hub for innovation aiming to transform U.S. manufacturing. This open-source project is now accessible on GitHub and has already garnered attention from over 50 entities, including equipment manufacturers, industrial end users, and universities, eager to explore its vast potentials.

As the world leans more towards sustainable and efficient manufacturing processes, technologies like Slicer 2 could play a critical role. Its development marks a significant milestone in the evolution of additive manufacturing, paving the way for the production of objects on a scale and with a precision that was once deemed impractical. The future of 3D printing, particularly for large-scale applications, looks brighter than ever with Slicer 2 leading the charge.

For everyone from the architects dreaming of 3D-printed buildings to aerospace engineers designing parts for the next generation of spacecraft, Slicer 2 offers a glimpse into a future where the only limit to what we can print is the extent of our imagination.