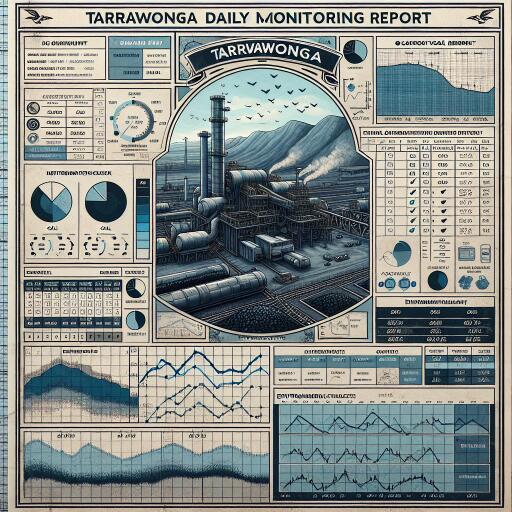

Exploring the Daily Monitoring Insights at Tarrawonga Mine: A Comprehensive Review

In the ever-evolving landscape of coal mining, operational management tools have become invaluable assets. At the heart of these advancements, the Tarrawonga mine stands out for its meticulous daily monitoring practices. Through an in-depth analysis, this article delves into the essence of their monitoring techniques and the impact of external factors on their data collection.

The core practice at Tarrawonga involves the utilization of sophisticated monitors that cater to various aspects of mining operations. These devices serve more than just regulatory compliance; they are pivotal in managing the mine’s day-to-day operations effectively. Unlike standard procedures where certain criteria dictate operational measures, Tarrawonga’s approach is uniquely flexible, adapting to the nuances of mining activities without rigid benchmarks.

The Intricacies of Noise Monitoring

One aspect of their monitoring regimen focuses extensively on noise levels, specifically in the low frequency range (20-630 HZ). This range, indicative of equivalent mining noise levels, is crucial for ensuring that the operations are in harmony with their surrounding environment. Yet, it’s pivotal to note that these readings might encapsulate sounds not solely attributable to mining activities. This acknowledgment showcases a level of transparency in their operation, highlighting that not all noise can be controlled or directly linked to their activities.

Occasionally, elevated noise levels have been observed, but these anomalies are often tied to external events unrelated to mining. This distinction is crucial, ensuring that the mine’s operational integrity remains unchallenged by phenomena beyond their control.

Data Collection Challenges

Data integrity is a cornerstone of effective operational management. However, the path to accurate data collection is fraught with challenges, chief among them being the susceptibility of monitoring equipment to environmental factors. Instances of data unavailability due to servicing needs, power outages, or communication interruptions are not uncommon. Moreover, adverse weather conditions, like heavy rain, further exacerbate these challenges, leading to instances where the average readings need recalculating to account for missing data.

This recalibration process is a testament to the mine’s commitment to precision. Even when faced with data gaps, efforts to recalibrate and estimate readings underscore a dedication to maintaining a detailed and accurate operational picture. Notably, these recalculations are clearly marked, maintaining transparency and accountability in their reporting process.

Conclusion

Tarrawonga mine’s daily monitoring practices illustrate a sophisticated blend of technology and transparency. By navigating the complexities of noise monitoring and overcoming the hurdles in data collection, the mine exemplifies how modern mining operations can operate responsibly and efficiently. Their commitment to adapting and recalculating in the face of challenges ensures that operational management is not just about adhering to standards, but about striving for operational excellence and environmental harmony.

As the mining industry continues to evolve, the practices at Tarrawonga offer valuable insights into the potential of technology and meticulous monitoring in driving forward sustainable and efficient operations.